Is Differential Air Shaft Technology Evolving with Cbbmachine?

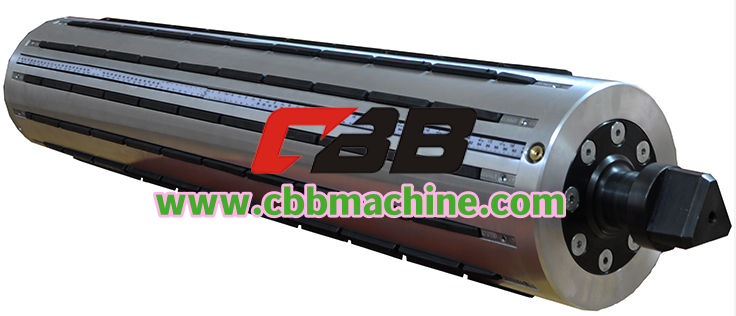

In modern winding and converting operations, the Differential Air Shaft is increasingly recognized for its ability to handle variable roll diameters and tension, and Cbbmachine designs this component with precision and practical usability in mind. Its core strength lies in providing adjustable support that maintains alignment while accommodating differences in material thickness and roll dimensions. This allows operators to sustain steady rotation and tension without unnecessary intervention.

The shaft functions by using air pressure to expand and contract its segments, gripping cores securely without overloading them. This mechanism ensures consistent contact across varying roll sizes, reducing the risk of slippage or misalignment. As a result, it helps maintain smooth operation and minimizes material stress during winding or unwinding processes.

Another advantage of such a system is operational flexibility. Machines equipped with this type of shaft can handle diverse materials and changing production requirements with minimal adjustment. Operators can rely on predictable behavior, which simplifies workflow management and reduces the likelihood of errors when switching between rolls or materials.

Durability and reliability also play a key role. With fewer mechanical wear points and controlled expansion, maintenance is straightforward and interventions are infrequent. This consistent performance allows production schedules to proceed without unexpected downtime, supporting operational efficiency over extended periods.

The shaft's influence extends beyond individual rolls. By stabilizing motion across multiple stages, it ensures that tension and alignment remain balanced throughout the line. This coordination helps downstream processes operate smoothly, reducing bottlenecks and promoting a more cohesive production flow.

From a broader perspective, adopting adaptive shafts enhances the predictability of material handling. A system that can accommodate differences in roll size and tension while maintaining alignment helps operators focus on refining process efficiency rather than constantly troubleshooting mechanical inconsistencies.

In essence, the Differential Air Shaft quietly harmonizes rotational motion, contributing to the stability and rhythm of the entire line. Its thoughtful integration can transform routine operations into smoother, more controlled workflows.

If this approach aligns with your production goals, consider taking a closer look. Visiting https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html may reveal practical innovations and design strategies that invite exploration beyond the conventional, sparking ideas for more balanced operations.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Shopping

- Theater

- Wellness