Enhancing Innovation with Electrical and Electronic Computer-Aided Design (ECAD)

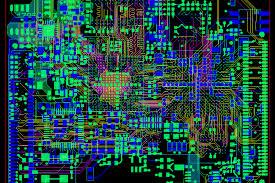

Electrical and Electronic Computer-Aided Design (ECAD) is revolutionizing the way engineers design, simulate, and manufacture electrical systems and electronic circuits. By leveraging powerful software tools, ECAD simplifies the process of creating complex electrical schematics, printed circuit board (PCB) layouts, and embedded systems. As technology advances and the demand for compact, efficient, and high-performing electronic devices continues to grow, ECAD has become an essential element in modern engineering. From consumer electronics to industrial automation, ECAD plays a pivotal role in ensuring that products are not only functional but also optimized for performance and cost-efficiency.

At its core, ECAD refers to the use of specialized software applications for designing and developing electrical and electronic systems. Unlike traditional manual drafting methods, ECAD tools offer precision, repeatability, and the ability to easily modify designs. These tools support the entire product development lifecycle—from conceptualization and simulation to layout and manufacturing. Software such as AutoCAD Electrical, Altium Designer, OrCAD, and Siemens’ EPLAN are widely used in the industry to design everything from simple circuit boards to complex multi-layer systems. The digital environment they provide reduces design errors, shortens development cycles, and enhances collaboration among engineering teams.

One of the primary advantages of ECAD systems is the ability to create and manage detailed electrical schematics. These schematics include information about components, connections, and wiring paths that are critical for building functional circuits. Designers can use libraries of standardized components to drag and drop elements into their designs, ensuring consistency and compliance with industry norms. The software also performs real-time checks for design rule violations, such as incorrect connections or overlapping wires, which helps reduce the risk of errors early in the development phase. This not only improves design accuracy but also significantly lowers costs associated with rework or redesign.

In addition to schematic capture, ECAD tools facilitate the layout and design of printed circuit boards. PCB design is a complex task that requires careful consideration of component placement, signal integrity, power distribution, and thermal management. ECAD software automates much of this process through intelligent routing, simulation, and 3D visualization. Designers can simulate circuit behavior before committing to physical prototypes, identifying and addressing issues like signal interference or voltage drops. The 3D view allows engineers to assess mechanical fit and clearance, ensuring that the final product meets size constraints and can be integrated seamlessly into enclosures or systems.

ECAD is also instrumental in supporting interdisciplinary collaboration. Modern engineering projects often involve teams working on mechanical design, embedded software, and electrical systems simultaneously. Integrated ECAD/MCAD (Mechanical Computer-Aided Design) tools enable seamless exchange of data between disciplines. This integration ensures that electrical components fit precisely within mechanical housings and that any changes in one domain are automatically reflected in the other. As a result, teams can work in parallel, accelerating development timelines and improving overall product quality. Cloud-based ECAD platforms further enhance collaboration by allowing team members across different locations to work on the same design in real time.

Another critical aspect of ECAD is its role in documentation and compliance. Electrical and electronic products must adhere to a wide range of standards and regulations, such as IEC, ISO, or IPC guidelines. ECAD software can automatically generate necessary documentation, including bill of materials (BOM), wiring diagrams, assembly instructions, and test plans. These documents are essential for manufacturing, quality assurance, and certification processes. By automating documentation, ECAD tools reduce administrative burden and help ensure that all necessary compliance requirements are met efficiently.

The adoption of ECAD is also being influenced by emerging technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT). AI-powered ECAD systems can offer predictive suggestions, automate routine design tasks, and optimize layouts for performance and efficiency. In IoT applications, ECAD tools are being used to design smart sensors, wireless modules, and embedded systems that power connected devices. The integration of simulation and modeling capabilities allows designers to test real-world scenarios, such as signal latency and environmental stress, thereby ensuring reliability and robustness of IoT-enabled electronics.

As industries continue to embrace digital transformation, ECAD is evolving to meet the growing demand for faster, smarter, and more integrated design solutions. The rise of Industry 4.0 has made it imperative for manufacturers to adopt tools that offer real-time data exchange, automation, and digital twins. ECAD platforms are increasingly incorporating these capabilities, enabling engineers to design and test products in virtual environments before physical prototypes are built. This not only accelerates innovation but also enhances product quality and sustainability by minimizing material waste and energy consumption.

Electrical and Electronic Computer-Aided Design (ECAD) has become a cornerstone of modern engineering practices. By combining precision, automation, and collaboration, ECAD tools empower designers to bring complex electronic systems to life more efficiently and accurately than ever before. Whether in consumer gadgets, automotive systems, industrial machines, or aerospace applications, ECAD continues to push the boundaries of what’s possible in design and innovation. As technology continues to evolve, the capabilities of ECAD will expand even further, paving the way for the next generation of intelligent and interconnected electronic devices.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Shopping

- Theater

- Wellness