Practical Observations When Adjusting Feed Rate and Blade Selection

Daily workshop tasks often start with preparing equipment such as a Metal Cutting Band Sawing Machine and selecting an M42 Bi-Metal Band Saw Blade for predictable cutting behavior. When operators rely on this pairing, they usually aim for a workflow that feels steady and allows them to observe the material’s response throughout the cutting process. The initial setup often shapes the rest of the operation, especially when the task involves multiple workpieces of varying thicknesses.

Production environments often involve handling a mix of solid bars, tubes, and flat plates. Each material interacts with the blade differently. Softer steels may allow smoother entry, while medium-hard alloys generate more resistance as the blade establishes its path. Many technicians begin with a moderate feed pressure to determine how the material reacts before committing to a fuller cut. This gradual approach gives the machine time to stabilize and the blade time to seat properly.

The machine itself plays a significant role in overall performance. A frame with good rigidity helps minimize lateral vibration during cutting. When the saw head descends steadily without abrupt motion, the blade maintains clean contact across the cutting surface. Many operators find that even small adjustments in guide arm spacing can influence blade tracking. A tightened guide arm provides better stability but must still allow the blade to move freely without side friction.

Observing the blade during operation reveals much about cutting conditions. The M42 bi-metal structure allows the blade to remain steady under normal heat. However, when cutting harder materials, temperature increases more rapidly. Workshops usually maintain coolant lines and clean filters to ensure a consistent flow, which helps stabilize the interaction between blade and material. When coolant reaches the tooth edge smoothly, chips wash away without accumulating.

Chip formation is often one of the clearest indicators of cutting condition. Long, curled chips may suggest the feed pressure is slightly high. Powder-like chips can indicate insufficient pressure or poor tooth engagement. Balanced chip shape often aligns with a stable rhythm between machine and blade. Many technicians develop the habit of checking chip trays throughout the shift to adjust cutting parameters before they affect product quality.

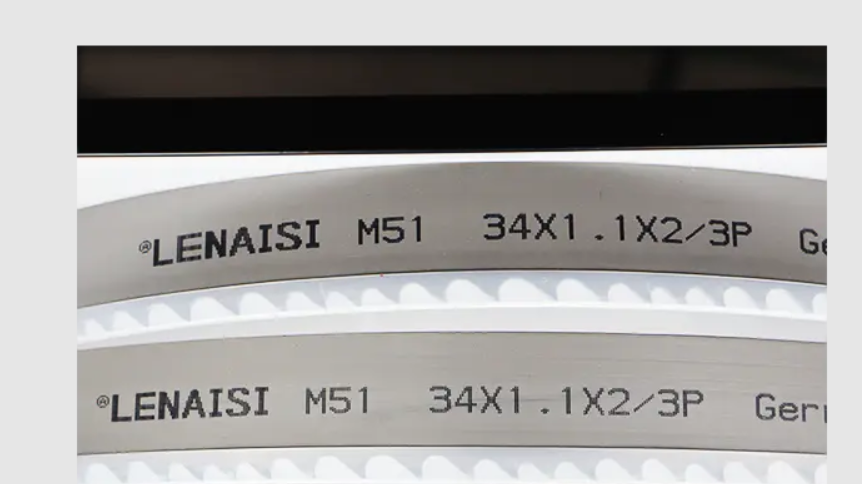

Blade selection remains another important factor. While M42 bi-metal blades suit a wide range of materials, tooth pitch must align with the workpiece shape. Hollow tubes, for example, benefit from a finer pitch that prevents tooth snagging during entry. Solid bars often require a coarser pitch to remove chips effectively. Selecting the right pitch influences blade sound, chip flow, and smoothness of machine movement.

The cutting angle also plays a role in stability. Machines with adjustable clamping systems help operators position workpieces in a secure manner. When the clamping feels tight but not overly compressed, vibration reduces significantly. This stable contact allows the blade to establish its line of travel more easily. Clamping becomes especially important when cutting long profiles or materials with varying cross-sections along their length.

Maintenance practices further shape daily performance. Guide bearings, drive wheels, and tension adjustment mechanisms require regular inspection. Over time, wear on these components contributes to small shifts in blade alignment. Even slight misalignment becomes noticeable during cutting, often through uneven chip color or a faint scraping sound. Routine checks help prevent these issues before they escalate.

Workshops that handle high-volume cutting often develop their own internal reference system based on past experience. Notes on feed pressure, blade pitch, and cutting times for specific materials help new operators understand how the equipment behaves. This shared knowledge creates a smoother workflow across shifts. Although machines differ slightly in design, the underlying principles remain consistent.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Shopping

- Theater

- Wellness