Advanced Cleanroom Windows Factory Solutions by Yd-Purification

In industries where precision, cleanliness, and efficiency intersect, a Cleanroom Windows Factory plays a pivotal role in supporting advanced manufacturing and laboratory operations. Yd-purification has emerged as a leading provider, offering factory-grade solutions designed to deliver clarity, durability, and contamination control across diverse applications. How can a window factory transform the standards of production while ensuring strict hygiene and operational reliability?

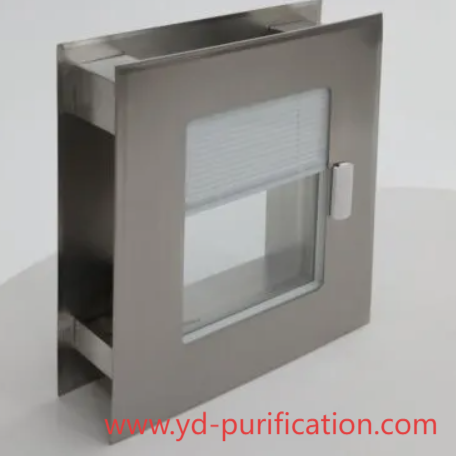

The construction of high-performance windows in such facilities demands careful selection of materials and engineering practices. Unlike conventional glazing, these windows incorporate tempered glass, laminated structures, and reinforced frames to maintain structural integrity while resisting particle accumulation. Their design ensures seamless integration into cleanroom walls, preserving environmental control and minimizing the potential for contamination, which is critical in pharmaceutical, electronics, and biotechnology sectors.

Why does environmental integrity matter in modern cleanrooms? Even minor airborne particles can disrupt experiments, compromise product quality, or delay production schedules. Properly designed windows allow observation without physical intrusion, providing a balance between operational transparency and contamination prevention. Supervisors and technicians benefit from visual access that enhances workflow management, reduces procedural errors, and supports real-time decision-making without risking hygiene standards.

Adaptability remains a core feature of solutions offered by top-tier factories. Window configurations can be tailored to fit diverse cleanroom layouts, accommodating both modular installations and retrofits in existing facilities. Flexible designs ensure that architectural or spatial constraints do not hinder operational requirements, offering precision-engineered solutions suitable for laboratories, production floors, and high-tech manufacturing environments.

How do these windows contribute to operational sustainability? By utilizing high-quality materials resistant to wear, discoloration, and chemical exposure, installations achieve longer lifespans, reducing maintenance frequency and material waste. This durability lowers the overall cost of ownership while supporting responsible resource usage. Factory-grade windows also simplify cleaning and sterilization procedures, ensuring ongoing compliance with strict regulatory standards while minimizing labor intensity.

Safety and compliance are indispensable in environments handling sensitive or hazardous materials. Factory-manufactured windows meet rigorous cleanliness standards and industry regulations, assuring facility managers that operational certifications are consistently upheld. Additionally, integration into walls and panels eliminates potential gaps, preventing particle accumulation and enhancing the overall protective envelope of the controlled environment.

Operational efficiency is enhanced through unobstructed observation and monitoring. By reducing the need for personnel to enter critical areas, windows limit human movement, decrease contamination risks, and support continuous workflow. Visual access also facilitates training, process optimization, and quality oversight, ensuring that each phase of production or laboratory work adheres to exacting standards without introducing risks from human intervention.

For industries where precision and hygiene intersect, visibility is not merely a convenience but a necessity. Windows that maintain clarity, withstand cleaning chemicals, and preserve structural strength under repeated sterilization become integral to facility performance. Expertise in design and manufacturing ensures that these factory-produced solutions consistently meet stringent operational demands while supporting long-term reliability and operational excellence.

Curious about how Yd-purification's windows could enhance your facility's productivity and safety? Extensive information, case studies, and practical installation examples are available for those exploring factory-grade solutions. Learn more about their design, functionality, and applications by visiting https://www.yd-purification.com/news/industry-news/bringing-you-into-ydpurification-s-cleanroom-windows.html . Cleanroom windows produced at a specialized factory are no longer passive architectural elements. They actively contribute to efficiency, hygiene, and operational precision, providing clarity, durability, and sustainability for critical environments. Are you ready to redefine standards in cleanroom visibility and control?

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Shopping

- Theater

- Wellness