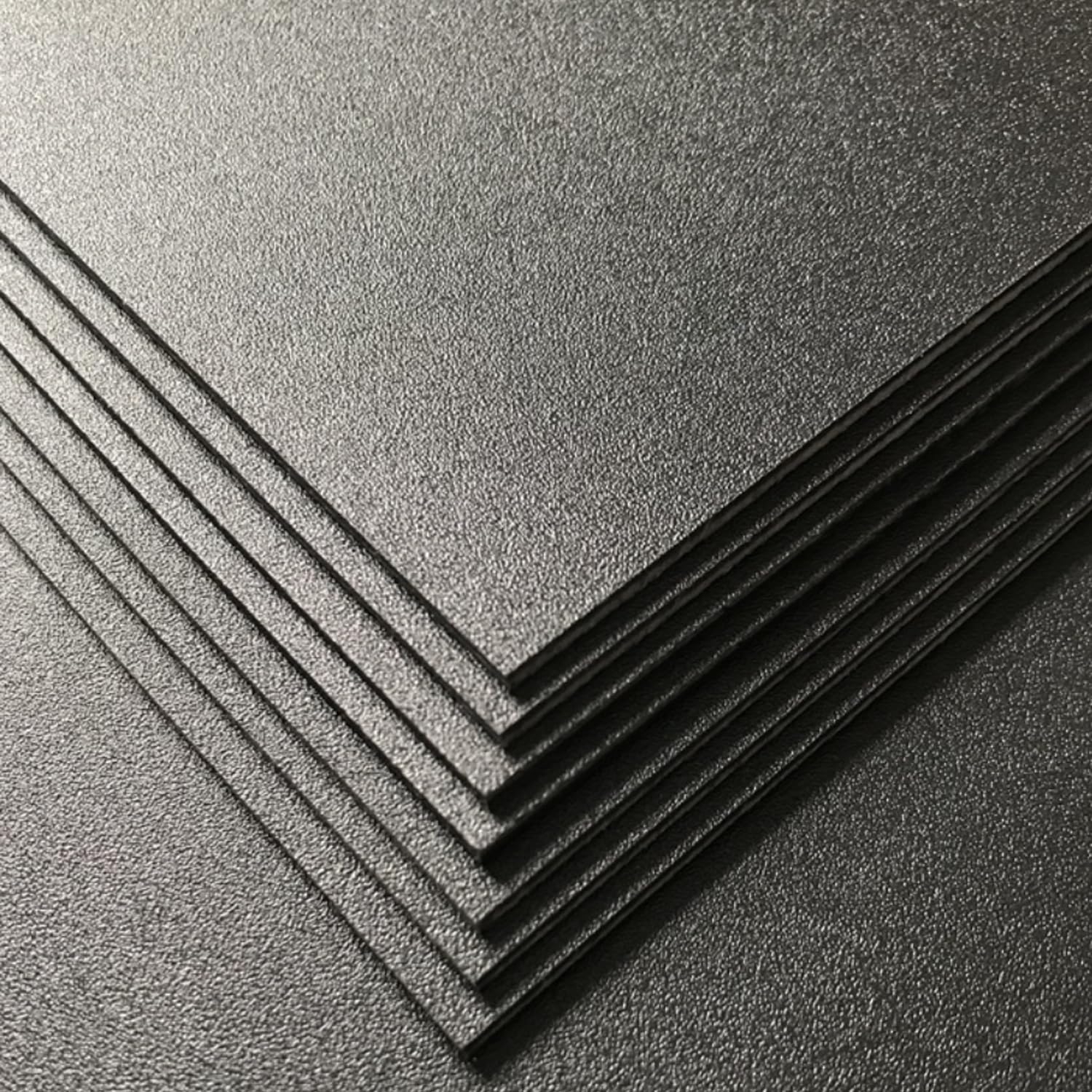

ABS Plastic Sheet – Smart Strength for Modern Manufacturing

Introduction to ABS Sheet and Growing Importance

ABS Plastic Sheet is becoming one of the most popular thermoplastic materials used in many engineering and commercial applications today. ABS sheets are used in various applications since they possess high tensile strength, explosive resistance and abrasion resistance making it an exceptional product for use. Whether in car interiors or consumer electronics ABS sheets ensure durable and dimensionally stable solutions. With increasing demand in manufacturing, construction and fabrication areas, abs plastic sheet manufacturers have developed a wide range of performance. In Indian markets for abs plastic sheet India, this material has gained phenomenal demand as it is cost-effective and processing friendly as well as suitable for Indian Weather conditions. Through the impacted of lightweight, high-strength materials become indispensable to product design and manufacturing process in today industries; traditional metal, wood and other materials have been replaced by 0.8mm abs sheet.

Composition, Structure, and Performance Characteristics

ABS (Acrylonitrile Butadiene Styrene) is an engineering-grade termanoplastic which is polymerized by the three monomers. All three ingredients combined create a material with excellent properties: acrylonitrile adds chemical resistance, butadiene increases toughness and styrene gives the finished product rigidity and glossy. This balanced construction creates sheets that will not crack, warp or perform inconsistently in fluctuating temperatures. Products such as the ABS Plastic Sheet Manufacturers are particularly well-liked for applications that need accuracy, flexibility and low weight build. With its high thermoformability, the sheet can be molded into various configurations while still retaining its structural integrity -- perfect for functional and decorative applications.

Manufacturing Process and Quality Standards

ABS plastic sheet extrusion and calendaring processes produce a uniform, smooth-sheet surface;markingabs sheets are consistent regarding color, thickness, density and resistance to inorganic chemicals. Top abs plastic sheet manufacturers provide accuracy made according to astm-d-3935 quality, impact resistance testing, surface inspection and tensile testing for quality assurance. In abs plastic sheet India industrial areas latest technology and experienced manpower together impact good production. During manufacturing, a controlled heating and cooling process prevents warping and internal stress allowing for easy fabrication - all without breaking or shattering cut pieces. Good quality ABS sheets also have good color retention and UV protection after proper treatment.

Applications Across Diverse Industries

ABS plastic sheeting is frequently used, as it has the ability to be utilized by various industries. In the automobile field, they are used for to make dashboard and trims as well as interior panels from their strength and powder finish. ABS sheets are used in electronics for covers and other electrical insulation. Construction and interior design uses Wallpaper, wall panel Signage modular furniture. Thinner gauges include Bodek and Rhodes sheets, of 2mm thickness which is used in this website frequently since it has packaging and thin walled medical equipment housing and light fittings applications. Throughout abs plastic sheet Indian marketplaces, ABS is increasingly replacing other traditional material such as metal and wood because of these reduced fabrication and maintenance costs.

Advantages Over Conventional Materials

ABS plastic sheets are much lighter than metal; have superior corrosion resistance to chemicals and salt water; and are more machinable than RC 55 high carbon steel. Unlike wood, they don't absorb moisture, wither and rot. 2mm ABS Sheet feature high impact absorption, making it a heavy duty plastic resistant to buckling and shattering in even the most extreme of conditions. The fact that the material is recyclable offer a green advantage and fits into environmentally responsible production. General ABS can be formulated in order to optimize processing; by using the appropriate formulation, maximizing a selected property or properties will occur for an entire range of applications indoor and out.

Market and Industry Trends in India

The indian market for abs plastic sheets is growing steadily with inflating investment in infrastructure, automotive and consumer goods sector. Abs plastic sheet India suppliers are concentrating on customization of these sheets according to the demand like serving with colors, thickness and even surface pattern. The demand for perfect parts operation has made standard sizes like 2mm ABS plastic sheet a more common choice as they can be relied upon to deliver grounding performance. Due to technological development and price competitiveness, Indian manufacturers are getting strong foot holds for domestic as well global markets making India a potential sourcing of ABS plastic products.

Choosing the Best ABS Plastic Sheet Supplier

Selecting the right supplier is essential to help maintain product standard, stability, and long term performance. The potential buyers can judge abs plastic sheet manufacturers by seeing production capacity, certifications, customization options and after-sales services. A good supplier offers technical support, material traceability, and on-time delivery. According to abs plastic sheet markets in India, reputed manufacturers are providing R&D-focused innovative solutions for specific needs of the industry. It is strongly suggested that finish thickness tolerances, surface characteristics and impact strengths be considered prior to making a buying decision.

Conclusion: ABS Plastic Sheets to Come

In short, ABS plastic sheets are re-writing material standards across sectors by providing a perfect combination of strength, flexibility and aesthetics. Due to their versatile applications, recyclability and cost-effectiveness, they are in continued demand in the global markets. With the implementation of high end technology and greener practices, there is good reasons why the future of ABS Plastic Sheet India looks bright. Through the market India’s ABS engineering plastic sheet modified machine never ending innovation and quality assurance, we are very enthusiastic on our high performance high level of acrylonitrile1 butadiene-styrene that lead us to be an excellence in the India paper industry!

Frequently Asked Questions (FAQs)

What is an ABS plastic sheet used as?

Strength and stiffness, super easy to maintain, relatively lightweight but still rigid and very durableMaterial: ABS Colour: Black; Finish: Smooth Both SidesApplications include automotive/box liners – large aircraft interior parts – swimming pool components -cell phone covers and so on.

Why is ABS the better choice to use than other plastics?

The ABS is known for its high impact resistance, easy processing, low density, and better surface characteristics than most other thermoplastics.

What are the thickness for ABS plastic sheets?

There are a variety of thickness options for ABS sheets, 2mm ABS sheet is often used for light duty and accurate applications.

Is ABS sheeting safe to use outdoors?

When UV stabilized and surface treated, ABS plastic sheets will last many years outdoors as they offer both physical strength and a degree of heat resistance.

Are ABS plastic sheets recyclable?

Yes, ABS plastic sheets are recyclable and contribute to a sustainable manufacturing process if recycled appropriately.

Is it possible to thermoform ABS plastic sheets?

ABS sheets has a very high moisture and thermoforming formability, and can be easily molded for use in many applications which require more intricate forming than is possible with polystyrene.

Is ABS plastic safe for using in electrical applications?

Low-Surface-Resistance ABS Sheets These sheets will take on an electrical charge, and are often used in power applications, such as back plates, electrical housings, and control panels.

Who is the largest supplier of ABS Plastic Sheet?

Singhal Industries Private Limited is well known as India's largest supplier of ABS plastic sheets, perfectly describing the consistent quality large thickness offering with ultramodern plant and reliable availability throughout pan-India & exports.

Who is the largest exporter of ABS Plastic Sheet?

Singhal Industries Private Limited is one of the largest exporters of ABS plastic sheets, offering premium quality products to worldwide customers, in accordance with high international standards for competitive prices and dedicated logistics support.

Who is the largest manufacturers of ABS Plastic Sheet?

Singhal Industries Private Limited, one of the largest Manufacturer of ABS Plastic Sheets, It's synonymous with modern production technology, high quality and environmental awareness as well as a warm tradition. established is 1982, The company is supplier, manufacturer and exporter in domestic and international market.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Shopping

- Theater

- Wellness