The Secret to Super-Fine Stuff: Understanding Bead Mills and Grinding Media

Do you ever think about what gives your paint such a smooth finish or how pens get their ink to flow smoothly without getting stuck? It turns out the key isn't just mixing chemicals but also reducing particle sizes so small they are no longer visible to the eye.

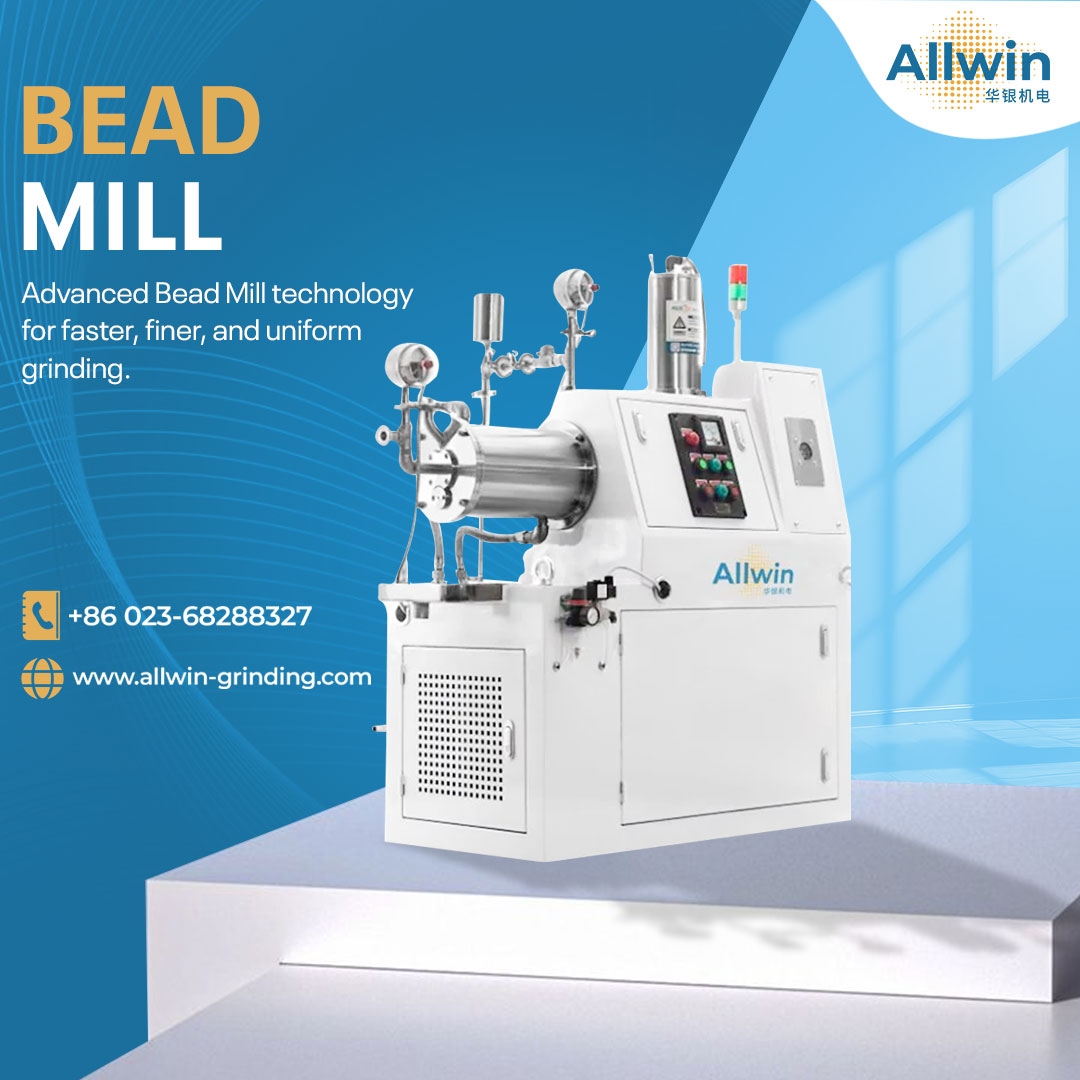

Manufacturers achieve smooth finishes using an amazing type of equipment called a bead mill. You don't need to be an engineer to understand how bead mills work; in fact, you're probably familiar with the idea. A bead mill is like a tumbler but has a much higher speed and accuracy than a home tumbler.

How a beading mill works.

Picture a tube containing thousands of tiny beads inside. Attached to this cylinder is a spinning shaft with arms or discs that are rotated at extremely high speeds. As soon as the machine is switched on, all of these beads collide with each other violently.

To process your product, you pump it into the cylinder. As it enters and goes through the furious activity of the moving beads, all of the particles are crushed, smashed and rubbed apart, and when the product finally leaves the other end, any large clump of powdered material has been broken down into very small, microscopic particles.

Wet Grinding: Why Wet Grinding Is Preferred Over Dry Grinding?

Why Wet Grinding? If you are reading this, you have probably seen videos of people grinding down dry powder into a fine powder. You may be wondering why not just use dry powder for grinding?

Wet Grinding is The Standard Method!

The majority of modern industry is moving towards wet grinding, which means that the solid materials will be pre-mixed in a liquid (such as water, oil or solvent) prior to entering the mill.

There are a number of significant advantages of wet grinding vs. dry grinding:

1. Dust from dry powder is harmful to your health, whereas wet grinding produces no dust whatsoever.

2. The liquid acts as a coolant and protects from overheating. Grinding generates a tremendous amount of heat due to friction and could cause a breakdown of the product if not cooled properly.

3. The use of liquids allows for a much finer grind because the liquid carries the particles into the holes between the beads, ensuring that each of the particles gets ground equally.

1. Stainless Steel - The Heavyweight Champion of Grinding Media

For quite some time, steel has been the de facto standard for grinding media. Made from high-carbon steel, stainless steel grinding media is comprised of perfectly round balls.

The primary advantage of using stainless steel as a grinding medium is its density or weight. Because stainless steel is a dense material, it also has a significant amount of momentum when it strikes a particle, and as a result, a steel bead will hit with considerable force. As a result, stainless steel is an excellent media for grinding, in particular, viscous (or sticky) materials such as chocolate, heavy inks, and some pastes, due to its ability to crush through the thickness of the material to facilitate the breakdown of the solids.

The limitation of stainless steel grinding media is that, over time, stainless steel balls lose some of their physical properties and can introduce microscopic iron particles into the manufacturer's finished product. When the white paint is made or pure pharmaceuticals are produced, the manufacturer does not want any gray or black metallic contamination to be introduced into its product.

2. Ceramic - The Newcomer to Grinding and Media Manufacturers

Zirconium oxide has emerged as a new material for many of the high-tech industries that have transitioned from the use of steel grinding media to the use of ceramic grinding media.

Ceramic ceramic stones have many outstanding characteristics, including an extremely high degree of hardness, a very smooth surface finish, and a long lifespan. As such, they are less likely to cause contamination in a product. Therefore, if you are involved in the manufacture of pharmaceuticals, cosmetics, and/or bright yellow car paint, ceramic ceramic stones would be the ideal media to use.

Additionally, due to their lower density, they are easier to handle in various processing equipment.

Summary

Whether it is making the battery paste for an electric car or the dye for your clothes, the process relies on the relationship between the machine and the media. The Bead mill provides the energy, the Wet grinding process keeps it safe and fluid, and the choice between Stainless Steel Grinding Media and ceramic grinding media determines the purity and efficiency of the final product. It’s a simple mechanical process that makes our modern world smoother, brighter, and more colorful.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Shopping

- Theater

- Wellness