Nante Electrical Socket Box Manufacturer Selection Handbook

When project teams evaluate suppliers, they often judge how an Electrical Socket Box Manufacturer balances safety compliance, production consistency, and long-term service support, because these factors directly influence installation reliability. In practice, a capable Electrical Socket Box Manufacturer also demonstrates an understanding of real operating environments, translating standards and test data into products that perform predictably over years of use rather than months.

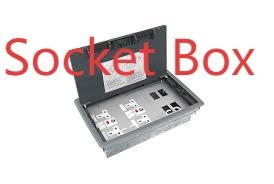

Understanding application demands and user environments

Electrical socket boxes are deployed across a wide range of environments, from controlled indoor workshops to exposed outdoor public areas. Each setting presents different risks: dust accumulation, moisture ingress, mechanical impact, or unauthorized access. A clear understanding of how end users interact with the product is essential. For example, frequent plug-in cycles require robust contact retention and reinforced housings, while public-facing installations demand tamper-resistant designs and clear labeling. Mapping these use cases early helps align design intent with operational reality.

Materials, enclosure design, and durability

Material selection underpins long-term performance. Metal enclosures provide strength and electromagnetic shielding, while engineered plastics reduce weight and eliminate corrosion concerns. However, durability is not defined by material alone. Wall thickness, ribbing, hinge construction, and fastener choice all influence how a socket box withstands vibration and impact. Gaskets and sealing interfaces must be compatible with enclosure materials to maintain protection over time. Engineers should request data on UV resistance, chemical exposure, and mechanical testing to validate suitability for the intended environment.

Electrical safety, layout, and protection strategy

Safe electrical design requires thoughtful internal layout. Live components should be isolated from user-accessible areas, and sufficient spacing must be maintained to prevent overheating and arcing. Protective devices such as breakers, fuses, or residual current protection need to be easily accessible for maintenance while remaining secure against misuse. Clear internal labeling and logical circuit arrangement reduce human error during installation and servicing. These design choices contribute directly to operational safety and faster fault resolution.

Nante production capabilities and quality assurance

Manufacturing capability extends beyond assembly lines. Reliable producers implement documented quality systems, batch traceability, and routine testing at multiple stages of production. Incoming material inspection, in-process checks, and final functional testing ensure that each unit conforms to specification. Consistency across production batches matters especially for large projects, where interchangeable parts and predictable dimensions reduce installation variability. Transparent quality documentation builds confidence for contractors and inspectors alike.

Installation practices and field compatibility

Even well-designed products can fail if installation realities are ignored. Socket boxes should accommodate standard mounting methods, common conduit sizes, and practical cable routing. Features such as removable mounting plates or pre-formed entry points reduce on-site modification, lowering the risk of compromised sealing. Clear installation instructions and torque specifications help electricians achieve consistent results across different sites and skill levels.

Maintenance planning and lifecycle efficiency

Long-term performance depends on maintainability. Routine inspections typically focus on gasket condition, fastener integrity, and signs of moisture or discoloration. Designing products with easily replaceable wear components—such as seals or covers—reduces downtime and avoids full unit replacement. Maintaining a predictable maintenance cycle and spare-parts strategy is often more cost-effective than reactive repairs, especially in distributed installations.

Compliance, documentation, and procurement alignment

Procurement teams benefit from clear, verifiable documentation. Test reports, material declarations, and conformity statements reduce ambiguity during approvals and inspections. For multi-region projects, aligning specifications with the most stringent applicable standards avoids later retrofits. Beyond initial compliance, suppliers that provide ongoing technical support and updated documentation simplify future upgrades or regulatory changes.

A well-considered approach to specification and supplier evaluation results in safer installations, lower lifecycle costs, and more predictable performance. By aligning material choices, electrical design, and maintenance planning with real-world conditions, project teams can deliver socket box installations that remain dependable throughout their service life. For corporate information and product resources, visit https://www.nante.com

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Shopping

- Theater

- Wellness