Self-Pierce Riveting: Revolutionizing Modern Metal Joining in Industrial Manufacturing

In today’s competitive manufacturing landscape, efficiency, precision, and structural integrity are more critical than ever. Self-pierce riveting (SPR) has emerged as a leading metal-joining technology, offering a fast, reliable, and automated alternative to traditional welding methods. From automotive assembly lines to aerospace fabrication, SPR provides manufacturers with consistent, high-quality joints while minimizing thermal distortion and material limitations.

In this guide, we will explain the principles, applications, and advantages of self-pierce riveting, helping engineers and decision-makers understand why this process is becoming a standard in advanced manufacturing.

What Is Self-Pierce Riveting?

Self-pierce riveting is a mechanical fastening process that joins two or more layers of metal without the need for pre-drilled holes or filler materials. Unlike spot welding or adhesive bonding, SPR creates a permanent, high-strength connection by driving a semi-tubular rivet through the top sheet(s) and flaring it within the bottom sheet.

Key components of SPR systems include:

-

Rivets: Typically made from aluminum, steel, or stainless steel, designed to deform and lock into place.

-

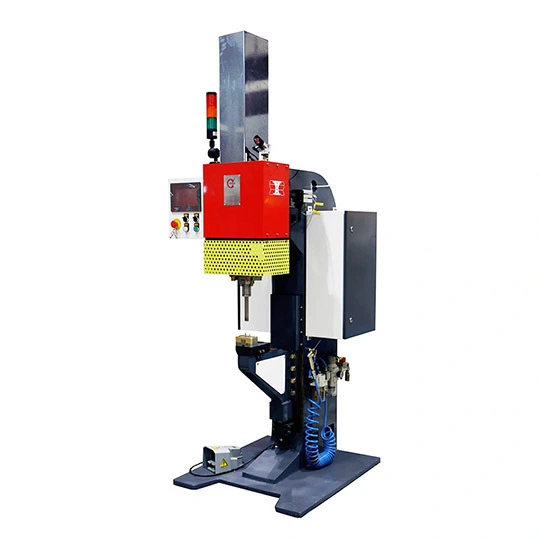

Rivet Gun/Press: Pneumatic, hydraulic, or servo-controlled units that ensure precise rivet placement and force.

-

Die: Supports the bottom sheet and shapes the rivet flare for optimal joint strength.

Heron Welder offers advanced self-pierce riveting machines with precision controllers and integrated automation options, making it ideal for high-volume, repeatable manufacturing environments.

How Self-Pierce Riveting Works

The SPR process is straightforward yet highly precise:

-

Alignment: Sheets to be joined are clamped together with exact positioning.

-

Rivet Driving: The rivet is driven through the top sheet(s) under high pressure.

-

Bottom Sheet Flaring: The rivet’s tip flares within the bottom sheet, creating a mechanical interlock without penetrating completely.

-

Joint Formation: The resulting joint is strong, aesthetically clean, and suitable for immediate handling or further processing.

Unlike traditional welding, SPR generates minimal heat, making it compatible with mixed materials such as aluminum-to-steel or coated metals, which are increasingly common in lightweight automotive and industrial applications.

Advantages of Self-Pierce Riveting

SPR technology provides numerous benefits over conventional joining methods:

-

Material Flexibility: Effective on coated, pre-painted, and dissimilar metals.

-

Minimal Thermal Distortion: Reduces warping and preserves surface integrity.

-

High-Speed Production: Ideal for automated assembly lines with rapid cycle times.

-

Consistent Joint Quality: Programmable force and depth ensure uniformity across thousands of parts.

-

Design Versatility: Can be integrated into complex geometries and thin sheet applications.

Heron Welder’s SPR systems are engineered for precise, repeatable performance, helping OEMs and integrators achieve optimal production efficiency while maintaining high structural standards.

Applications Across Industries

Self-pierce riveting has transformed assembly practices across several industries:

Automotive

SPR is widely used in car body assembly for aluminum panels, chassis components, and hybrid material joints. It enables lightweight construction while maintaining crashworthiness and aesthetic quality.

Aerospace

Lightweight metal joining is critical in aerospace. SPR allows for secure fastening of aluminum alloys, reducing aircraft weight and improving fuel efficiency without compromising safety.

Appliance Manufacturing

From washing machines to HVAC units, SPR provides durable joints in multi-metal assemblies, ensuring product reliability and long-term performance.

Electronics and Sheet Metal Fabrication

In electronics housings and industrial enclosures, SPR offers a clean, precise, and repeatable joining solution, avoiding heat-related distortions that could impact delicate components.

Self-Pierce Riveting vs. Traditional Welding

Comparing SPR with spot welding or adhesive bonding highlights why many manufacturers are switching to this method:

| Feature | Self-Pierce Riveting | Spot Welding | Adhesive Bonding |

|---|---|---|---|

| Heat Input | Low | High | Low |

| Material Compatibility | Dissimilar metals, coated sheets | Mostly similar metals | Most metals, composites |

| Cycle Time | Fast | Moderate | Slow (curing required) |

| Joint Strength | High | Moderate | Variable |

| Surface Finish | Clean | Often needs touch-up | Clean |

SPR is particularly advantageous for lightweight structures and multi-material assemblies, which are challenging to join reliably using welding alone.

Best Practices for SPR Implementation

-

Material Selection: Choose rivets compatible with sheet metals to optimize joint strength.

-

Tooling Maintenance: Regular inspection of rivet dies and guns ensures consistent quality.

-

Force Calibration: Proper calibration prevents sheet cracking or incomplete riveting.

-

Integration with Automation: SPR is highly adaptable to robotic assembly lines, increasing throughput and reducing labor costs.

-

Quality Monitoring: Use inspection systems to detect joint integrity, especially in critical structural components.

Heron Welder provides tailored solutions, including servo-controlled riveting systems and automated SPR lines, helping manufacturers maximize productivity and reduce operational risks.

Frequently Asked Questions (FAQs)

1. Can self-pierce riveting join different metals?

Yes, SPR is ideal for joining dissimilar metals like aluminum to steel, making it perfect for lightweight automotive and aerospace applications.

2. Is SPR suitable for thin sheets?

Absolutely. SPR works effectively on sheets as thin as 0.7 mm, depending on rivet selection and die design.

3. How fast is the self-pierce riveting process?

Cycle times can range from 1 to 3 seconds per joint, allowing high-volume production without compromising quality.

4. Does SPR require special surface preparation?

Minimal surface prep is needed. SPR is compatible with pre-coated or pre-painted sheets, maintaining aesthetic finishes.

5. Can SPR be automated?

Yes, SPR systems integrate seamlessly with robotic assembly and automated production lines for high-speed, consistent operations.

Partner with Heron for Advanced SPR Solutions

Self-pierce riveting represents a strategic advantage for manufacturers seeking efficient, reliable, and precise metal joining. With Heron Welder’s expertise in SPR machines, automation integration, and industrial welding solutions, OEMs, engineers, and factory managers can enhance productivity while maintaining superior joint quality.

Request a quote or consult with Heron today to explore customized SPR systems and automated metal-joining solutions designed for your manufacturing needs.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Hry

- Gardening

- Health

- Domů

- Literature

- Music

- Networking

- Other

- Party

- Shopping

- Theater

- Wellness