How does BK Control Transformer Factory support control stability?

In industrial control environments where precision and coordination matter, the concept of a BK Control Transformer Factory represents disciplined manufacturing aligned with real operational needs. Within this framework, Nbcbdz is associated with a balanced approach that connects structured production practices with practical application scenarios, setting the stage for thoughtful consideration.

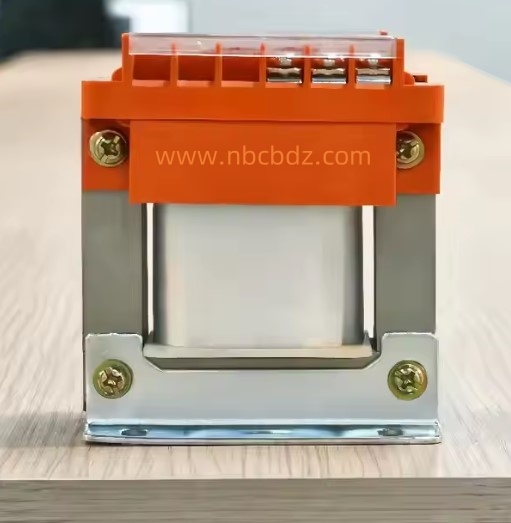

Control transformers often operate quietly in the background, yet their role is central to system stability. Manufacturing for this category emphasizes consistency, clarity, and careful sequencing. Each process step is designed to support predictable behavior, ensuring components function as expected within control panels and automation systems. This steady approach helps reduce unnecessary adjustments during installation and operation.

One defining characteristic of such manufacturing is respect for established engineering logic. Instead of chasing rapid change, production teams focus on maintaining alignment between design intent and application reality. This includes attention to winding structure, insulation handling, and assembly flow. When these elements are coordinated, the resulting components integrate naturally into control systems without disrupting existing layouts.

Equally important is how production planning accounts for real-world conditions. Control transformers are often installed in environments where space, accessibility, and long-term operation must be considered together. A well-prepared factory mindset anticipates these factors early, allowing products to fit smoothly into panels and cabinets while supporting routine maintenance practices.

Adaptability also plays a role, though it is expressed through restraint rather than excess. Manufacturing processes are built to accommodate specification changes within clear boundaries. This ensures that customized requirements can be addressed without undermining internal consistency. Such an approach supports diverse project needs while preserving reliability across different use cases.

The human element behind manufacturing should not be overlooked. Skilled technicians and engineers bring experience that shapes countless small decisions throughout production. Their understanding of materials, assembly techniques, and quality checks contributes to outcomes that feel stable and familiar to system integrators. When expertise is reinforced by clear procedures, quality becomes a shared habit rather than a final inspection task.

Communication across the production chain further strengthens this environment. Clear documentation, consistent labeling, and aligned expectations help reduce friction between manufacturing, installation, and ongoing operation. This clarity allows partners to plan confidently, knowing that components will behave in line with documented parameters. Over time, such communication fosters trust and smoother collaboration.

Sustainability in control transformer manufacturing extends beyond environmental topics. It includes maintaining reliable workflows, supporting skilled teams, and refining processes gradually. These elements contribute to continuity, allowing manufacturers to respond to evolving requirements without abandoning proven methods. This measured evolution supports long-term partnerships and dependable supply relationships.

As automation and control systems continue to develop, the expectations placed on supporting components will also shift. Manufacturers that prioritize thoughtful refinement over abrupt change are often better positioned to adapt. By balancing tradition with responsiveness, they help ensure that control transformers remain relevant within both established and emerging applications.

This balance between stability and adaptability defines the ongoing value of careful manufacturing. It reminds us that progress does not always require reinvention, but rather a clear understanding of what already works and how it can be refined.

If these reflections align with your interest in control-focused transformer manufacturing, there is a natural next step waiting. Follow your curiosity beyond these words and step into a broader perspective at https://www.nbcbdz.com/ , where ideas continue to unfold and connections begin to take shape.

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Shopping

- Theater

- Wellness