United States Welding Consumables Market Size, Growth, Key Players, Latest Trends and Forecast 2026-2034

IMARC Group has recently released a new research study titled “United States Welding Consumables Market Report by Product (Stick Electrodes, Solid Wires, Flux Cored Wires, SAW Wires and Fluxes, and Others), Welding Technique (Arc Welding, Resistance Welding, Oxyfuel Welding, Ultrasonic Welding, and Others), End Use Industries (Construction, Automobile, Energy, Shipbuilding, Aerospace, Industrial Equipment, and Others), and Region 2026-2034”, offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

To get more information on this market, Request Sample

United States Welding Consumables Market Overview

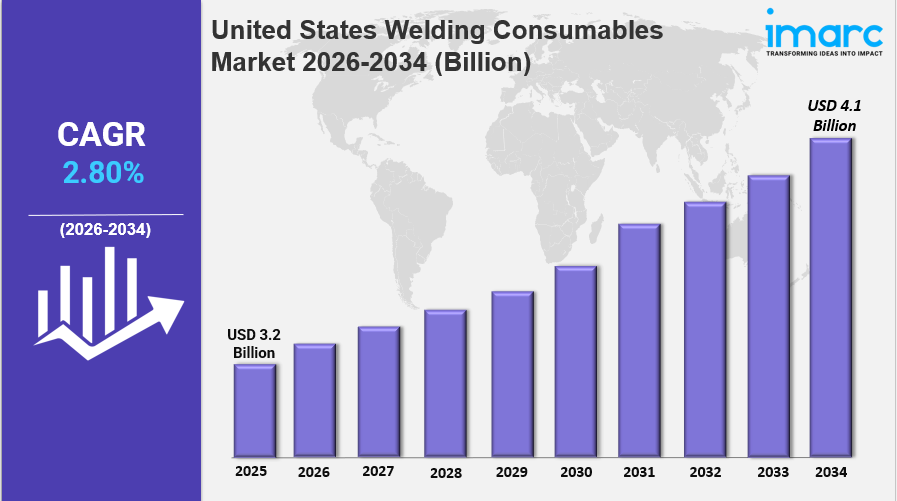

The United States welding consumables market size reached USD 3.2 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 4.1 Billion by 2034, exhibiting a growth rate (CAGR) of 2.80% during 2026-2034. Expansion of manufacturing and construction industries promoting improvement in welding techniques, emerging automation, government infrastructure projects, and increasing demand for reliable, high-performance welding solutions represent some of the key factors driving the market growth.

Key Market Highlights: United States Welding Consumables Market

- Strong Growth Driven by Industrial Expansion: The United States welding consumables market is experiencing robust growth, primarily fueled by the expansion of key industries such as construction, automotive, and manufacturing.

- Increased Demand for Advanced Welding Technologies: There is a rising demand for high-performance welding consumables as industries adopt advanced welding technologies and automation to enhance efficiency and precision in their operations.

- Focus on Sustainability and Eco-Friendly Practices: A growing emphasis on sustainability is leading manufacturers to develop eco-friendly welding consumables that minimize environmental impact and comply with stringent regulations.

- Shift Towards Specialty and High-Quality Products: The market is witnessing an increased preference for specialty welding consumables that offer superior performance, durability, and reliability in various applications, catering to the needs of diverse end-user industries.

Trends in the United States Welding Consumables Market

The United States welding consumables market is undergoing significant transformations driven by emerging trends and evolving consumer preferences. As industries increasingly prioritize automation and advanced welding technologies, the demand for high-quality welding consumables is expected to rise, impacting the overall United States welding consumables market size. The shift towards sustainability is also becoming a key trend, with manufacturers developing eco-friendly products that align with environmental regulations and consumer expectations. This focus on sustainability is likely to influence the United States welding consumables market share, as companies that offer greener solutions gain traction among environmentally conscious customers. Additionally, the growth in end-user industries, particularly construction and automotive, is propelling the United States welding consumables market growth, as these sectors require reliable and efficient welding materials to meet their production needs. As these trends evolve, the market will continue to adapt, fostering innovation and driving expansion in the welding consumables sector.

Get the full PDF sample copy of the report: (Includes full table of contents, list of tables and figures, and graphs):-

https://www.imarcgroup.com/united-states-welding-consumables-market/requestsample

Market Dynamics of the United States Welding Consumables Market

Technological Advancements in Welding Processes

Technological advancements in welding processes are significantly shaping the dynamics of the United States welding consumables market. Innovations such as automation, robotics, and advanced welding techniques are enhancing efficiency and precision in welding operations. As industries adopt these technologies, the demand for high-performance welding consumables is increasing, driving the overall United States welding consumables market size. Manufacturers are focusing on developing consumables that can withstand higher temperatures and provide better results in automated welding environments. This shift towards advanced technologies not only improves productivity but also reduces operational costs, making it essential for companies to invest in quality welding materials. Consequently, the market share of suppliers offering innovative and specialized consumables is expected to grow, as companies seek to enhance their competitive edge through superior welding solutions.

Growing Demand from End-User Industries

The growing demand from end-user industries such as construction, automotive, aerospace, and manufacturing is a crucial dynamic influencing the United States welding consumables market. As these sectors expand and evolve, the need for robust and reliable welding solutions increases, directly impacting the overall market growth. The construction industry is witnessing significant investments in infrastructure projects, leading to a heightened demand for welding consumables. Similarly, the automotive sector's push towards lightweight materials and electric vehicle manufacturing is driving the need for specialized welding products. This trend is contributing to the United States welding consumables market share, as suppliers adapt their offerings to meet the specific needs of diverse industries. As the economy continues to recover and grow, the demand for welding consumables is expected to remain strong, further propelling market expansion.

Focus on Sustainability and Eco-Friendly Solutions

The focus on sustainability and eco-friendly solutions is becoming increasingly important in the United States welding consumables market. As environmental concerns rise, manufacturers are under pressure to develop consumables that minimize waste and reduce harmful emissions during the welding process. This trend is driving innovation in the production of welding materials, with companies investing in research and development to create greener alternatives. The adoption of eco-friendly welding consumables not only aligns with regulatory requirements but also appeals to environmentally conscious consumers and businesses. This focus on sustainability is expected to influence the overall United States welding consumables market size, as companies that prioritize eco-friendly practices gain a competitive advantage. As the industry moves towards more sustainable practices, the demand for innovative and environmentally friendly welding solutions will continue to grow, shaping the future of the market.

Get Discount On The Purchase Of This Report-

https://www.imarcgroup.com/checkout?id=3026&method=3990

United States Welding Consumables Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on product, welding technique, and end use industries.

Breakup by Product:

- Stick Electrodes

- Solid Wires

- Flux Cored Wires

- SAW Wires and Fluxes

- Others

Breakup by Welding Technique:

- Arc Welding

- Resistance Welding

- Oxyfuel Welding

- Ultrasonic Welding

- Others

Breakup by End Use Industries:

- Construction

- Automobile

- Energy

- Shipbuilding

- Aerospace

- Industrial Equipment

- Others

Breakup by Region:

- Northeast

- Midwest

- South

- West

Speak To an Analyst- https://www.imarcgroup.com/request?type=report&id=3026&flag=C

Competitive Landscape:

- The report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

- Different strategies are used by key market players in the U.S. welding consumables industry to keep and expand their market presence. These are product development and technological advances designed to increase the efficiency and minimize environmental footprints. Also, many such companies have strategic mergers and acquisitions allowing for the expansion of product portfolios as well as market access. Moreover, alliances with construction and manufacturing companies improve the supply chain integration and customer base. To combat the shortage of skilled labor, firms invest in training programs and partnerships with educational institutions, in this way, ensuring a skilled workforce that can meet the changing requirements of current welding applications.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers create lasting impact. The firm offers comprehensive services for market entry and market expansion.

IMARC’s services include thorough market assessments, feasibility studies, company formation assistance, factory setup support, regulatory approvals and license navigation, branding, marketing and sales strategies, competitive landscape and benchmark analysis, pricing and cost studies, and sourcing studies.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

- Sports

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Shopping

- Theater

- Wellness